High-Pressure Fuel Pump Repair & Restoration

What is a High-Pressure Fuel Pump?

The high-pressure fuel pump is a critical component of the diesel fuel injection system. Its function is to pressurize diesel fuel and deliver it to the injectors for injection into the combustion chamber. With correct pressure and metering, the fuel is finely atomized and combusts efficiently, ensuring diesel engine power output and fuel efficiency.

After approximately 2,000–3,000 operating hours, the pump components typically undergo wear and loss of sealing, leading to insufficient injection pressure or incorrect injection timing. While replacement is common practice, Origin Pipe provides a cost-effective alternative through repair and restoration, restoring pump efficiency to around 70–80% of a new pump.

Construction of a High-Pressure Fuel Pump

The main components include:

- Plunger and barrel assembly – generates high fuel pressure.

- Delivery valve – controls fuel delivery during each pumping cycle.

- Camshaft and tappet (cam follower) – actuates the plunger to control injection timing.

- Springs, gaskets, and seals – ensure tight sealing and stable operation.

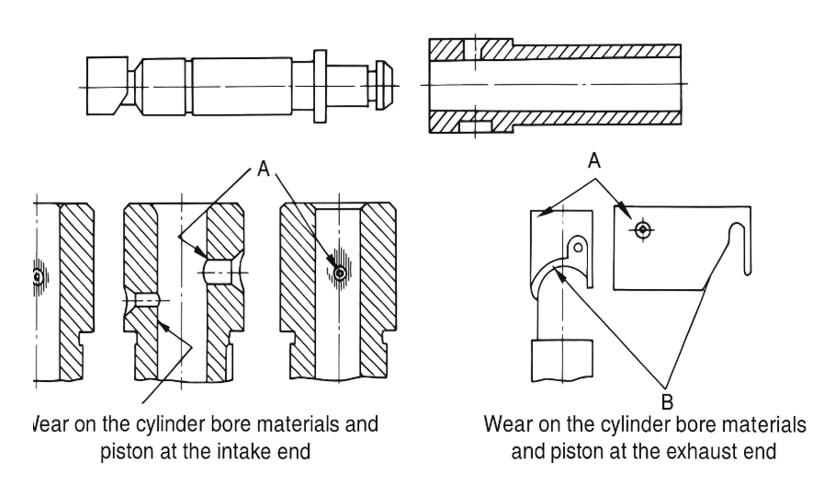

Typical failure points: plunger–barrel wear leading to reduced sealing and leakage.

Common failure positions of high-pressure pump piston–cylinder

Origin Pipe’s Restoration Process

Our process includes:

- Precision grinding and lapping of the plunger–barrel assembly to restore sealing capability.

- Ultrasonic cleaning / thorough cleaning of the pump housing and fuel passages to remove carbon deposits and rust.

- Replacement of worn components such as gaskets, seals, and springs.

- Calibration of injection pressure and timing in accordance with OEM specifications.

.jpg)

High-pressure pump equipment

Test & Calibration Equipment

After restoration, the pump is tested on a fuel injection test bench to verify:

- Correct injection pressure,

- Proper atomization,

- Stable fuel delivery across all operating conditions.

Only pumps that pass the test are delivered back to customers.

Applicable to a wide range of diesel engines, including:

- Marine main engines and auxiliary engines (ship generators),

- Industrial diesel generator sets,

- Locomotive diesel engines,

- Heavy-duty mining trucks.

.jpg)

High-Pressure Fuel Pump